Flange gaskets are used for improved joint performance.

They are considered much more superior than the conventional ring or full-face gaskets. Although pipe flange gaskets are usually used for all normal water and sewer service, they are especially useful in demanding services like in very large diameter flanged piping.

For specially designed long-span installations, involving 2 or 3 or more lengths of pipe or with any underground flanges, flange gaskets are of great help because they could be subjected to undesirable beam loading.

These gaskets are available in numerous standard materials in various thickness and hardness options for various flange sizes. Flange gaskets are also available with adhesive on one or both sides or without adhesive. Most materials are available starting at 1/32” thick and can be supplied up to 1” thick. Some manufacturers supply flange gaskets in wide rolls from which you can cut your flange gaskets to size. Flange gaskets are also available to your exact requirements. Pipe flange gaskets are being very frequently used for flanged joints which are subjected to extreme chemical attacks.

Materials used:

A flange gasket is a type of gasket made to fit between two sections of pipe that are flared to provide higher surface area. Flange gaskets come in a variety of sizes and are categorized by their inside diameter and their outside diameter.Flange gaskets are made of various materials like:

- Rubber:Neoprene, EPDM, Nitrile, EVA, Silicone, Cork and Cork Rubber

- Closed Cell Foam:Cross-linked Polyethylene, PVC

- Plant Fiber

- Cellulose Fiber

What Are the Different Types of Gaskets?

The most common types of gaskets are:

- Gaskets used in piping (flange gaskets)

- Gaskets used in vehicles (cars, boats, planes, trains)

- Gaskets with certain material properties (cork, rubber paper etc.)

- Gaskets used for a particular function (for pressure, temperature, or chemical resistance)

- Bespoke or custom made gaskets

What is the difference between a RTJ, FF, and RF flange on seals and thermowells?

Pipe gaskets (otherwise known as flange gaskets) are made from wide range of materials such as rubber, non-asbestos and graphite. The gaskets can be bought as either Full Faced (with bolt holes) or Inner Bolt Circle (IBC, ring type or raised face).

There are many standards in gasket for flanges of pipes.

The raised face, RF, is the standard process connection on our third party seals and thermowells. Both have options for a RTJ and FF type flange connections. The Raised Face (RF) is the most common type used in process plant applications.

The gasket surface of the flange is raised above the bolting circle face. A Ring-type Joint (RTJ) can also have a raised gasket face with the difference being the ring groove machined in this face. This groove will accommodate a steel ring gasket for flange mating. The Flat Face, FF, flange has a gasket surface that is in the same plane as the bolting circle face. None of these three flange types are interchangeable between types, i.e. RTJ flange cannot be mated to a RF flange.

There are many standards in gasket for flanges of pipes. The gaskets for flanges can be divided in major 4 different categories:

- Sheet gaskets

- Corrugated metal gaskets

- Ring gaskets

- spiral wound gaskets

Sheet gaskets are simple, they are cut to size either with bolt holes or without holes for standard sizes with various thickness and material suitable to media and temperature pressure of pipeline.

Ring gaskets also known as RTJ. They are mostly used in offshore oil- and gas pipelines and are designed to work under extremely high pressure. They are solid rings of metal in different cross sections like oval, round, octagonal etc. Sometimes they come with hole in center for pressure equalization.

Spiral wound gaskets are also used in high pressure pipelines and are made with stainless steel outer and inner rings and a center filled with spirally wound stainless steel tape wound together with graphite and PTFE, formed in V shape. Internal pressure acts upon the faces of the V, forcing the gasket to seal against the flange faces.

Types of flange gaskets

Materials for gaskets can be divided into three main categories:

- Non-Metallic types

- Semi-Metallic types

- Metallic types

Non-Metallic gaskets are usually composite sheet materials are used with flat-face and raised-face flanges in low Pressure Class applications. Non-metallic gaskets are manufactured from arimid fiber, glass fiber, elastomer, Teflon® (PTFE), graphite etc.. Full-face gasket types are suitable for use with flat-face flanges. Flat-ring gasket types are suitable for use with raised face flanges.

ASME B16.21 covers types, sizes, materials, dimensions, dimensional tolerances, and markings for non-metallic flat gaskets.

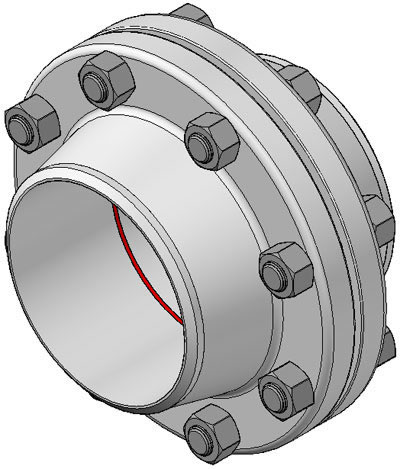

Bolted Flange connections

A bolted flange connection is a complex combination of many factors (Flange, Bolts, Gaskets, Process, Temperature, Pressure, Medium). All these various elements are interrelated and depend upon one another to achieve a successful result.

The reliability of the flanged joint depends critically upon competent control of the joint making process.

Some other disadvantages of flange connections:

- Each flange connection can leak (some people claim that a flange connection is never 100 percent leak proof).

- Flanged pipe systems need much more space (just think of a pipe rack).

- Insulation of flanged pipe systems is more expensive (special flange caps).

Advantages and disadvantages of Socket Weld fittings

The pipe need not be beveled for weld preparation. Temporary tack welding is no needed for alignment, because in principle the fitting ensures proper alignment.

The weld metal can not penetrate into the bore of the pipe.

They can be used in place of threaded fittings, so the risk of leakage is much smaller. Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP), or liquid penetrant (PT) examination methods.

Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

Comments