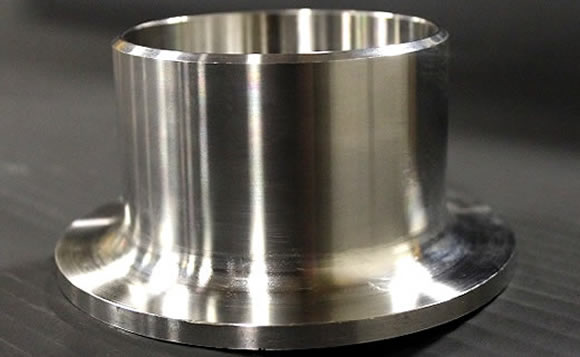

Lap Joints are consisted of three series

| Nominal Pipe Size | Outside Diameter at Bevel | Length | Radius of Fillet | Diameter of Lap | |

| A | B | ||||

| NPS | D | L | R | G | |

| 1/2 3/4 1 | 21.3 26.7 33.4 | 51 51 51 | 3.0 3.0 3.0 | 0.8 0.8 0.8 | 35 43 51 |

| 11/4 11/2 2 | 42.2 48.3 60.3 | 51 51 64 | 5.0 6.0 8.0 | 0.8 0.8 0.8 | 64 73 92 |

| 21/2 3 31/2 | 73.0 88.9 101.6 | 64 64 76 | 8.0 10.0 10.0 | 0.8 0.8 0.8 | 106 127 140 |

| 4 5 6 | 114.3 141.3 168.3 | 76 76 89 | 11.0 11.0 13.0 | 0.8 1.6 1.6 | 157 185 218 |

8 | 219.1 273.0 323.8 | 102 127 152 | 13.0 13.0 13.0 | 1.6 1.6 1.6 | 270 324 381 |

| 14 16 18 | 355.6 406.4 457.0 | 152 152 152 | 13.0 13.0 13.0 | 1.6 1.6 1.6 | 413 470 533 |

| 20 22 24 | 508.0 559.0 610.0 | 152 152 152 | 13.0 13.0 13.0 | 1.6 -- 1.6 | 584 641 692 |

- Type A & B Stub Ends are made similar to forging pipe fittings such as elbows and tees.

- Type C Stub Ends are made by customized dimensions.

Benefits of lap joint stub ends

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

The use of lap joint stub ends has these two advantages:

Reduces the overall cost of the flanged joint

Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Example:

For an SS316 pipe, instead of using a full 316 welding neck flange, a combination of an SS316 stub end and a carbon steel lap joint flange would do the same exact job, but the total weight of SS316 material would be lower, and the cost as well.

Essentially, stub ends allow to minimize the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

Facilitates the installation of the flange

The lap joint flange can be rotated on the pipe and simplify the alignment of the bolt holes of the mating flanges

It shall be noted that stud ends are becoming popular also in high-pressure applications (whereas they were used for low-pressure applications only in the past).

They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints.

The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

There are three different types of stub ends, Type A, B and C. Type A stub ends are machined to fit in a standard lap joint backing flange

We offer stub ends at highly competitive prices.

Lap Joint Stub End – The ‘mated’ pair to a Lap Joint Flange. Stub Ends are Fittings used in place of welded flanges where rotating back up flanges are desired. Stub Ends are typically manufactured by two methods, Type A & Type B and are available in two standard lengths , long (ANSI) or short (MSS) pattern.

Features:

- Thermal stability

- High mechanical strength

- Long functional life

Manufacturing standards of stub end:

- ASTM ASME A/SA 403

- MSS SP43 & SP75 ANSI B16. 9

- ANSI B16. 28 ASTM A815 ASTM B363 B366

- DIN2605 DIN2615 DIN2616 DIN2617

- GB12459GB13401

- JIS2313

Specifications:

- Grades: ASME / ASTM SA / A234

- Material:

- Stainless Steel, 316/316L Stainless Steel, 304/304L Stainless Steel and Chrome-moly

- Carbon steel

Technical Specifications:

- Thicknesses are based on ASME B16.48 specifications or the products can be manufactured to customer specifications.

- Standard surface finish is 125-250 RMS serrated finish.

- Other finishes available upon request.

- c/w a standard shop primer on carbon steel products for rust inhibitor purposes.

- Size: Available in all sizes and thickness

Usage:

Petroleum, Chemical, Power, Gas, Metallurgy, Ship-building, Construction, ect.

Using stub ends allows sections of the line to be opened for cleaning, inspection, or quick replacement etc, without the need to re-weld.

Specifications:- Grades: ASME / ASTM SA / A234

- Material: Stainless Steel

- Size: Available in all sizes and thickness

Comments