Stainless steel pipe fitting is part that connect pipe to pipe, its purpose to connect, control and change the direction, split, sealed, support various parts and components in pipeline system, selecting and preparing proper pipe fitting to joint together, there are various types, sizes, grades & specifications to meet specific requirement.

These valuable fittings are available in many different shapes, dependent on the intended purpose:

- – ‘Elbows’ are used to alter the pathway of a pipeline

- – ‘Reducers’ are needed to reduce or increase the size of the pipe bore size

- – ‘Tees’ or ‘Crosses’ are used to split the flow in the pipe multiple ways

- – ‘Caps’ are used if the pipeline needs to be closed off

Dimension:

Pipe Fittings are sized to Nominal pipe size (NPS) respectively, NPS ranges from1/2 inch to 24 inch, thicknesses are marked in schedule no, ranging from SC 5 to 80S, sizes tolerances should be controled in compliance with standard specifications in both outside and inside.

- 1/2” to 24” seamless type SCH 5S to XXS

- 2” to 48” welded type SCH 5S to XXS

Pipe fittings and their applications

Pipe and pipe fittings go hand-in hand. Just as pipes are used for a variety of residential, public and industrial applications, so also the pipe fittings. No pipes can be connected without the use of proper fittings and flanges. Pipe fittings allow pipes to be installed and connected or joined where necessary and terminated in the right place.

Such as Oil and gas industries, Midstream, Shipbuilding, Power plants, Food plants, Pharmaceuticals, etc.

Pipe fittings include a wide range of products in various shapes, sizes and materials. With rapid developments in the field of industrial fittings and continuous research work in this industry, various new products are manufactured. Some fittings have certain special features so that they can be fabricated on different principles like hydraulics, pneumatic depending on the end usage.

Fittings include a comprehensive range of products depending on various applications in which they are applied.

Fittings are used wherever liquids, gases, chemicals and other fluids are created, processed, transported, or used.

There is no end to applications of pipe fittings so long there is no end to the applications of pipes . While the list of piping applications continues to expand, its strength, flexibility, very good flow rates and high chemical resistance are qualities which are uniquely suited for the movement or transfer of liquids, steam, solids and air from one point to another.

Pipe fittings come in many forms with the most common being threaded fittings, socket weld fittings and buttweld fittings. This blog will explore the advantages of all three types, but especially the advantages of buttweld fittings and their applications.

- Chemical

- Municipal

- Food, Beverage& Dairy

- Oil and Gas

- Power

- Instrumentation

- Pulp and Paper

- Semiconductor

- Marine & dredging

- Sanitation

- Piping Systems

- Irrigation

- Residential

- Road construction

- Ventilation etc

Pipe fittings are essential parts of pipelines as they allow for the following:

- A change in direction for the liquid flowing through the pipes

- Branching of the pipe to allow the liquid to flow in two separate directions

- A reduction in pipe diameter

- The attachment of auxiliary equipment

- The end of the pipeline

All the buttweld fittings supplied by Special Piping Materials are designed in accordance to ASME standards.

Advantages:

Buttweld fittings can withstand pressures and temperatures in very harsh environments. They are generally considered to be the most robust welding fixture, no matter what industry it is required for. However, they do take a considerable time to fit and a highly skilled installer is required to weld them correctly on site.

- Welded connection offers a more robust, a stronger and a more leak-proof piping connections.

- The nature of the continuous metal structure provides added strength to the overall piping system.

- The smooth inner surface and gradual directional changes provide a seamless flow, thus minimising pressure drops and turbulence inside the pipe.

- Provide the option of various different turn radiuses due to the manufacture of Short Radius fittings, Long Radius fittings and 3R Elbows.

- They are cost effective compared to the counterpart fittings in the threaded or socket weld varieties.

- They have a long service life and are cost effective to purchase and deploy.

- Buttweld fittings can withstand corrosion and erosion more effectively than its socket weld and threaded equivalents.

- A welded system uses comparatively less space that the other alternatives.

Manufacturing method and process

A buttweld fitting is manufactured by the process of hot or cold forming, which means that it is bended and moulded to the correct shape. They are also heat treated to remove residual stresses and to achieve specific mechanical properties.

The ends of buttweld fittings have to be bevelled and the exact shape of the bevel depends upon the wall thickness of the pipe it is being attached to. The material of a buttweld fitting can be any one of a number of exotic materials such as super duplex, nickel alloy or 6% Moly. The majority of the time, the material of the fitting is the same as the pipe system that it is welded to.

Stainless steel material traits

The excellent raw material of BW pipe fittings are better performance in mechanical properties and beautiful surface.

| Grade | Carbon | Silicon | Manganese | Chromium | Nickel | Molybdenum | Sulfur | Phosphorous |

|---|---|---|---|---|---|---|---|---|

| WP 304 | 0,08 | 1,0 | 2.00 | 18.0 – 20.0 | 8.0 – 11.0 | – | 0,03 | 0,045 |

| WP 304L | 0,035 | 1,0 | 2.00 | 18.0 – 20.0 | 8.0 – 13.0 | – | 0,03 | 0,045 |

| WP 316 | 0,08 | 1,0 | 2.00 | 16.0 – 18.0 | 10.0 – 14.0 | 2.00 – 3.00 | 0,03 | 0,045 |

| WP 316L | 0,035 | 1,0 | 2.00 | 16.0 – 18.0 | 10.0 – 15.0 | 2.00 – 3.00 | 0,03 | 0,045 |

| WP 321 | 0,08 | 1,0 | 2.00 | 17.0 – 19.0 | 9.0 – 12.0 | – | 0,03 | 0,045 |

304 and 316L are the most used stainless steel grades, they are both high chromium austenitic grades, and can be met the most cases, and other grades are available, such as, 321/321H and 347/347H. Some special alloys are usually for elbow as well, like 904L, 2205.

There are also EN steel no. for opting, these equivalents include 1.4301, 1.4307, 1.4401, 1.4404, 1.4541, 1.4550, 1.4438 and 1.4539.

Stainless steel pipe fittings grades include:

- ASTM/ASME A403 WP 304-304L-304H-304LN-304N

- WP 316-316L-316H-316LN-316N-316Ti

- WP 321-321H

- WP 347-347H

- 2205 duplex material is available.

Pipe Fitting Standards

- ASME/ANSI B16.9 – Factory-Made Wrought Steel Butt-welding Fittings

- ASME/ANSI B16.11 – Forged Steel Fittings, Socket-Welding and Threaded

- ASME/ANSI B16.28 – Wrought Steel Butt-welding Short Radius Elbows and Returns

- ASME/ANSI B16.5 – Pipe Flanges and Flanged Fittings

- ASTM A403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

We can also provide pacified stainless steel and coated line fittings, threaded, socket-weld & coupled ends.

No job is too small or too large. Whether it’s a small project, plant shut down, line replacement, or stock requirement for ongoing operations Petropipe can help you meet your deadline.

Austenitic stainless steel

Austenitic stainless steel has austenite as its primary phase at both elevated and room temperature.

Super austenitic stainless steel

Superaustenitic stainless steels are defined as austenitic, iron-based alloys that have pitting resistance number (PREN) greater than 40.

Duplex Stainless Steel Pipe

Duplex Stainless Steel is a type of austenitic stainless steel that comprises of nickel and chromium majorly, along with other elements like nitrogen and molybdenum.

Main type of stainless steel fittings

We are as well providing offering extensive collection of Stainless Steel Elbow Pipe Fittings for Buildings and other related industries. Meanwhile, we charge lesser price for these SS Elbow Pipe Fittings. According to the different demands of our customers, we are providing a broad range of Stainless Steel Butt Weld Fittings to our customers.

Stainless reducer

Stainless steel reducer manufactured using superior grade raw materials.Stainless steel caps

Stainless steel caps are usually used for protecting the end of pipe and other fittings,Stainless steel tee

Stainless steel Tees and supply high quality in SUS304, SS316 gradeStainless Stub End

Stainless stub end are fittings used in place of welded flanges where rotating back up flanges are desired.Stainless pipe elbows

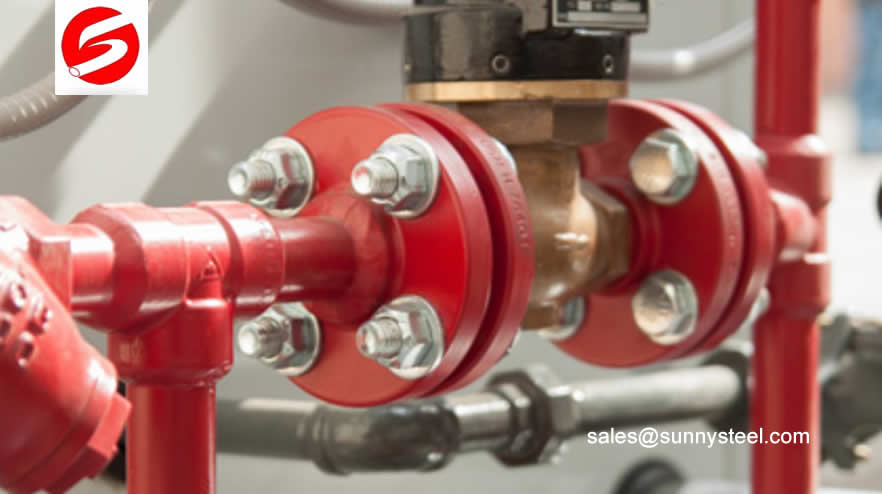

Stainless Steel Pipe Fittings are high in demand in the market for use in highly corrosive industrial conditions.Stainless Steel Flanges

Our company has gained immense accolades in the field of offering Stainless Steel Flanges to the clients.Packing of stainless steel pipe fittings materials

Butt welded stainless steel pipe fittings is stainless steel tube and fittings of the rim on the seam lap argon welding fittings, which normally takes plus welding welding.

Recommend search keywords

Compression type fittings connection is reliable and secure, convenient and speedy construction suitable for embedded installation, and maintenance-free update, the economy is relatively superior characteristics.

The entrapment stainless steel fittings

Stainless Steel Pipe Fittings

- ANSI SS Long Radius Elbows Dealers

- Stainless Steel Equal & Unequal Tee

- ASME/ANSI B16.9 SS Concentric Reducers

- SUS Steel Pipe Cap

- DIN Stainless Steel Reducing Nipple

- SS Pipe Bends Supplier in Africa

- Stainless Steel 45°, 90°, 180° Elbows

Stainless Steel Welded Pipe Fittings

- Stainless Steel Butt weld Pipe Fittings

- Stainless Steel Short Radius Elbows

- ASME SA403 Steel Fabricated Tees

- ANSI B16.28 Stainless Steel Eccentric Reducers

- UNS Steel End Cap Distributor

- Stainless Steel Stub End

- A403 Stainless steel 3D, 5D Elbow

Comments